Production process of fire-resistant aerated concrete blocks from GRANUGLASS

Fire-resistant aerated concrete block

lighter and with better thermal insulation properties thanks to the replacement of some of the sand with GRANUGLASS glass granules.

Composition and Proportions

(Example - Requiring Validation):

-

Portland cement (CEM I 42.5R): 15-20% (Binder)

-

Slaked lime (Ca(OH)₂): 5-10% (Loosener, pH adjuster)

-

Quartz sand (ground, fraction <0.5mm):40-55% (Main filler)

-

GRANUGLASS (Perlite expanded glass, fraction 0.25-0.5mm, PORAGLASS):5-15% (Partial replacement for sand. Improves fire resistance, lowers density, improves thermal insulation. Key modifying ingredient).

-

Water: 0.55-0.65 (water/binder ratio) - Exact amount depends on the moisture content of the ingredients and the desired consistency of the grout.

-

Powder/aluminium (Al) paste: 0.05-0.08% dry weight (Blowing agent - reacts with lime to form hydrogen).

-

Admixtures (optional): Bonding accelerators, plasticising agents (minimum quantities).

Note: these proportions are approximate and must be developed and verified in a laboratory for specific raw materials and production conditions. Using GRANUGLASS reduces density and improves fire insulation, but it may slightly reduce the compressive strength compared to standard cellular concrete of the same density. The optimum percentage of GRANUGLASS (usually 10–12%) is determined to achieve the best balance between fire resistance, strength, density, and cost-effectiveness.

Production process:

1. Preparation of raw materials:

- The sand is finely ground wet or dry to the required fineness.

- Cement, lime and GRANUGLASS are stored in silos.

- The clay paste and any admixtures are prepared in separate tanks.

- Water is dosed and heated/cooled to the desired temperature (approx. 40-50°C).

2. Dosing and Mixing:

- All dry ingredients (cement, lime, sand and GRANUGLASS) must be accurately weighed/measured according to the recipe.

- It is particularly important to dose GRANUGLASS precisely.

- The dry ingredients are loaded into a mixer (usually a planetary or turbine mixer).

Water is then added, after which dry/wet mixing begins for several minutes until a homogeneous mass is obtained. - Then, aluminium (Al) paste is added. The mixture is stirred briefly (15–60 seconds) to distribute the blowing agent evenly, but not for too long to avoid prematurely starting the gassing reaction.

3. Pouring into Moulds and Gasification (Swelling):

- The homogenised slurry is poured into partially filled (usually 40–60% by volume) steel moulds coated with a release agent.

- The moulds are then swiftly transferred to the pre-maturation zone.

- A gas-forming reaction then takes place: aluminium powder + lime + water → hydrogen (H₂) + calcium trisilicate (C₃AH₆). The released hydrogen causes the mixture to foam and increase in volume many times over, filling the mould.

- This gassing process takes 1–3 hours at a controlled temperature of approximately 40–70 °C and humidity. A characteristic pore structure is formed.

4. Trimming (Wire Cutting):

- Once the gassing phase is complete and the mass has partially set, obtaining what is known as 'green strength', it is hard enough to retain its shape but still soft enough to be cut.

- The mould is then removed. The large, monolithic 'loaf' of cellular concrete is then cut into precisely defined block dimensions and supplementary elements (lintels, U-profiles) with thin steel strings, both vertically and horizontally.

5. Autoclaving (Hardening):

- The cut blocks are placed on autoclave trolleys.

- The trolleys enter the autoclave (huge pressure vessel).

- The process takes 8-16 hours and takes place under strictly controlled conditions:

- Phase I (heating): A gradual increase in vapour pressure and temperature (up to 160–200 °C) occurs over the course of several hours.

- Phase II (isothermal): Maintenance of the maximum temperature and pressure (typically 10–12 bar) for 6–12 hours. Reactions to synthesise calcium silicates (tobermorite C₅S₆H₅), which give cellular concrete its final strength, durability and stability, take place under these conditions of high steam pressure. GRANUGLASS is stable under these conditions.

- Phase III (cooling): The temperature and pressure are gradually lowered over several hours to avoid cracking of the blocks.

6. Unloading, Quality Control and Packaging:

- The hardened blocks are removed from the autoclave and cooled to room temperature.

- They are then subjected to quality control checks, including measurements of their dimensions and density (kg/m³), as well as an assessment of their compressive strength and appearance.

- The blocks are then packed in shrink film on pallets, ready for transport and sale.

- Dimensions of finished product (examples vary according to manufacturer):

Most common Wall Block Dimensions:

| Parameter | Dimension options |

|---|---|

| Lenght (L) | 600 mm, 625 mm |

| Height (H) | 200 mm, 240 mm, 250 mm, 300 mm |

| Width (W) | 100 mm, 120 mm, 150 mm, 180 mm, 200 mm, 240 mm, 300 mm, 360 mm, 400 mm |

- Density: Classified by density (e.g. 400, 500 or 600 kg/m³). GRANUGLASS blocks have a slightly lower density than standard blocks of the same strength.

- Compressive strength class: Denoted by the letter LC (e.g. LC2.0, LC2.5, LC3.5, LC4.0, LC5.0 or LC6.0).

Description of the Finished Product:

- Appearance: A homogeneous, porous, light grey material (with cement and sand predominating). GRANUGLASS granules are usually visible on the cut surface as fine, light-coloured dots or lumps (white, grey or yellowish) with a diameter of 0.25–0.5 mm.

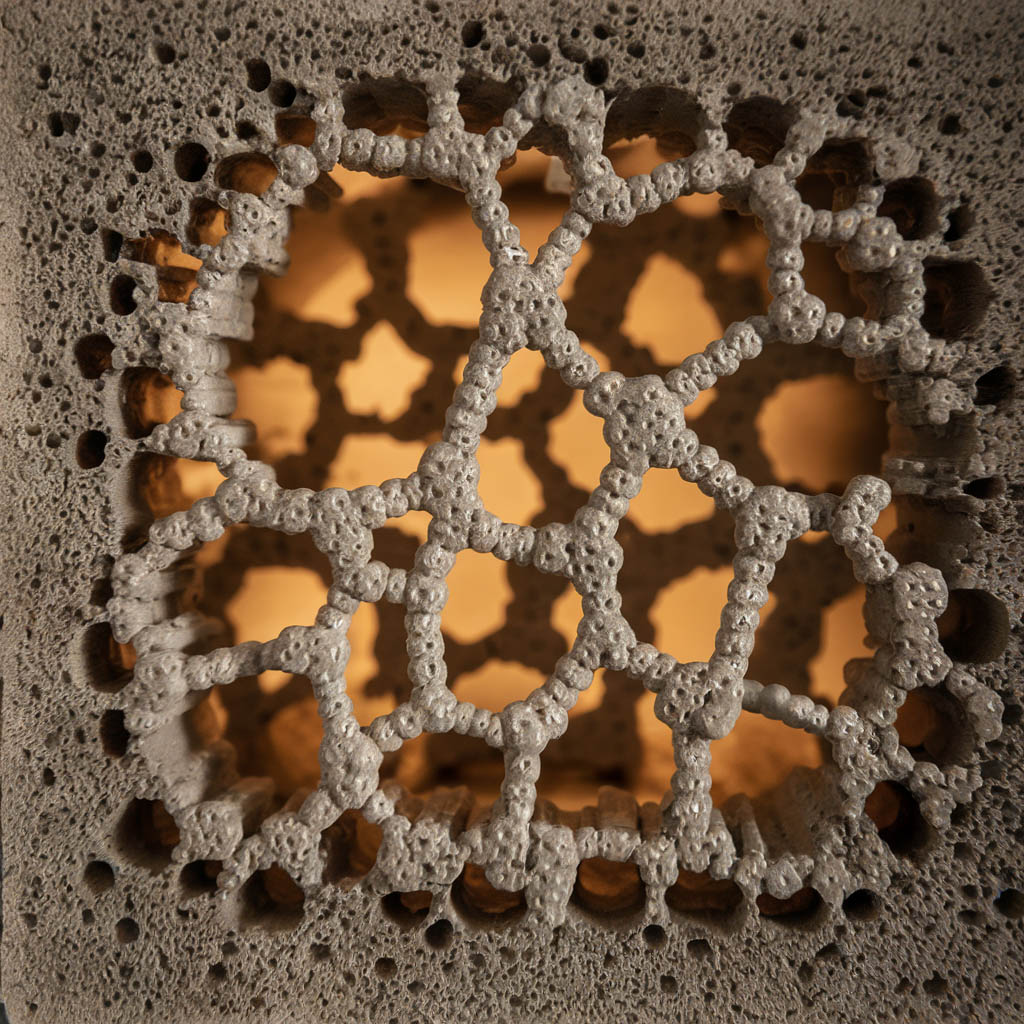

- Structure: a homogeneous, fine-porous, cellular structure consisting of closed air pores, which is characteristic of aerated concrete. GRANUGLASS granules are uniformly dispersed in this matrix.

Key Features:

- Improved fire resistance (REI): By replacing some of the sand with non-combustible GranuGlass, which acts as a thermal barrier within the pores, the blocks can achieve a higher fire resistance class (e.g. REI 240) at the same thickness as standard aerated concrete.

- Reduced density: GRANUGLASS is lighter than sand, resulting in a lower overall density of the blocks.

- Improved thermal insulation (λ): The lower density and the presence of glass granules improve the thermal conductivity coefficient (λ), i.e. improve thermal insulation.

- Good vapour permeability: It retains the high water vapour diffusion capacity characteristic of aerated concrete.

- Ease of handling: It can be easily cut, sawed, milled and chiselled using standard aerated concrete tools.

- Dimensional accuracy: High-precision cutting guarantees even, thin joints.

- Strength: It is available in different compressive strength classes (LC) and is suitable for load-bearing and partition walls.

- Frost resistance: High (when applied correctly).

- Environmental protection: Contains recycled material (GRANUGLASS).

Key Reservations:

- Formulation: The proportions given are estimates. The technologist must develop the actual optimum recipe in the laboratory and test it under production conditions, taking into account the exact parameters of all raw materials (especially the reactivity of lime and sand) and the desired final properties of the blocks (e.g. density, strength and fire resistance).

- Process: The process details (times, temperatures and pressures) may vary depending on the production plant and the raw materials used. The effect of the addition of GRANUGLASS on gasification kinetics and the hardening process needs to be verified.

- GRANUGLASS: Granules with a well-defined and stable fraction (0.25–0.5 mm) and low dust content must be used. Its brittleness requires care during transport and mixing.

- Certification: The finished product requires full testing and certification (including fire tests according to standards, e.g. EN 1364-1 and EN 13501-2), to confirm the declared fire resistance class (REI) and other performance properties.