Thermal Paint Insulation with Granuglass – Lightweight, Natural and Efficient

Our thermal insulation paint with Granuglass Expanded Glass offers a cutting-edge solution for protective and energy-saving coatings. By using natural expanded perlite instead of recycled glass fillers, we provide high insulation performance with exceptional purity and stability.

Thermal Resistance and Long-Term Durability

Adding Granuglass to thermal coatings delivers:

-

Lower thermal conductivity,

-

Improved UV resistance,

-

Increased protection against moisture and mold,

-

A lightweight, microporous structure that enhances breathability.

Compared to standard fillers like Poraver (based on recycled glass), Granuglass ensures a more stable, chemically neutral solution – free from contaminants and heavy metals.

Applications of Thermal Paint with Granuglass:

-

Exterior facades in passive and low-energy buildings

-

Surfaces exposed to extreme temperature fluctuations

-

ETICS insulation systems

-

Industrial interiors: warehouses, production halls, containers

Benefits for Manufacturers and Contractors:

-

Thinner coatings with the same insulation performance

-

High color and structure stability over time

-

Made from natural, VOC-free, microplastic-free raw materials

-

Easy to apply, compatible with most facade systems

Request a Sample or Contact Us

Looking to develop your own thermal insulation paint using natural expanded perlite?

Granuglass is the reliable raw material for professional applications.

Granulometry and Packaging

We offer various expanded perlite fractions tailored to your formulation:

- Standard: 0.1–0.3 mm,

- Optional: 0,25 - 0,5 mm

- Custom blends on request

Available in bags, BIG-BAGs, or loose bulk.

Description of Thermal Insulation Paint with GRANUGLASS (0.1–0.3 mm fraction)

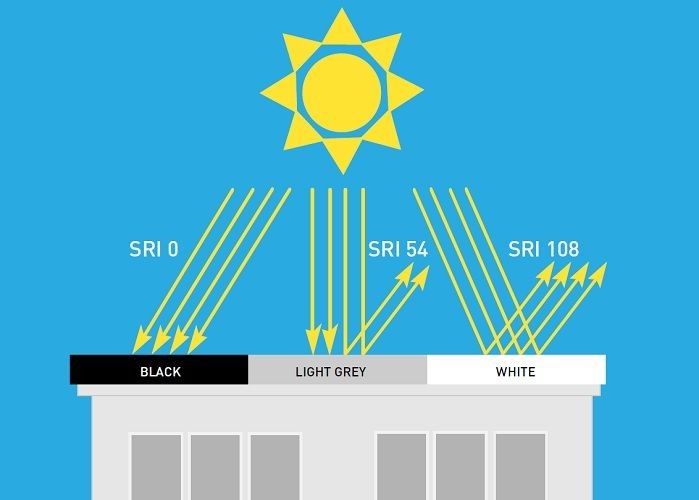

The thermal insulation paint with the addition of GRANUGLASS expanded glass granulate of fine fraction 0.1–0.3 mm is a modern mineral-polymer coating that provides thermal insulation and surface protection for exterior applications. Thanks to the use of lightweight expanded glass, the paint features very low thermal conductivity, a high total solar reflectance (TSR ~90%), and good vapor permeability.

The product is water-based, eco-friendly with very low VOC content (e.g., below 1 g/l), resistant to weather conditions, fungi, and bacteria, and allows easy application by roller, brush, or spray.

Composition of Thermal Insulation Paint

with GRANUGLASS (0.1–0.3 mm fraction)

| Component | Mass Content [%] | Function |

|---|---|---|

| Polymer dispersion (e.g., acrylic or styrene-acrylic) | 25–35 | Binder, flexibility, adhesion |

| Water | 30–40 | Solvent, carrier |

| GRANUGLASS expanded glass (0.1–0.3 mm) | 15–25 | Lightweight thermal insulation filler |

| Mineral fillers (e.g., silica, chalk) | 5–10 | Filling, strength enhancement |

| Pigments (e.g., titanium dioxide) | 1–3 | Color, opacity |

| Preservatives and biocides | 0.1–0.3 | Protection against microorganisms |

| Additives (anti-foam, flow improvers) | 0.1–0.5 | Application ease and stability |

Production Procedure of Thermal Insulation Paint with GRANUGLASS

-

Raw Material Preparation

-

Check quality and moisture content of expanded glass (0.1–0.3 mm fraction).

-

Weigh components according to formulation.

-

-

Mixing of Aqueous Phase

-

In a ribbon or planetary mixer, mix water with polymer dispersion, additives, and preservatives.

-

Mix until a homogeneous and stable emulsion is obtained.

-

-

Addition of Pigments and Fillers

-

Gradually add pigments and mineral fillers under continuous mixing to avoid agglomeration.

-

Mix until complete dispersion of components.

-

-

Addition of GRANUGLASS Expanded Glass

-

Gently add the expanded glass granulate to preserve its integrity and spherical structure.

-

Mix at low speed to avoid damage to the granules.

-

-

Quality Control of Paint

-

Check viscosity (e.g., Ford or Brookfield viscometer).

-

Check density, pH, and solids content.

-

Optional tests for thermal conductivity and solar reflectance under laboratory conditions.

-

-

Packaging and Storage

-

Fill paint into containers (e.g., 2L, 5L, 10L).

-

Store at 5–30°C, protected from frost and direct sunlight.

-

Key Technical Parameters of Thermal Insulation

Paint with GRANUGLASS

| Parameter | Typical Value / Range | Practical Significance |

|---|---|---|

| Thermal conductivity λ | approx. 0.0005 W/(m·K) | Very good thermal insulation |

| Total solar reflectance (TSR) | approx. 90% | Reflects solar radiation |

| Paint density | 1.1–1.3 g/cm³ | Lightweight coating, easy application |

| Viscosity (Ford 4) | 20–40 s | Optimal consistency for painting |

| Drying time | 2–24 h (depending on conditions) | Fast setting and curing |

| Weather resistance | High | Durability against UV, moisture, frost |

| Resistance to fungi and bacteria | Yes | Antifungal and antibacterial protection |

| Application temperature | from -30°C to +180°C | Wide application range |

| VOC content | < 1 g/l | Eco-friendly, environmentally safe |

Applications

-

Thermal insulation coating for residential and industrial building facades.

-

Protection of surfaces exposed to large temperature variations and solar radiation.

-

Thermal insulation in locations difficult to insulate with traditional materials.

-

Antifungal and antibacterial coating in humid environments.

Detailed Recipe for Thermal Insulation Paint (per 100 kg of finished paint)

| Component | Amount [kg] | Function |

|---|---|---|

| Acrylic polymer dispersion (40% solids) | 30.0 | Binder, flexibility, adhesion |

| Water | 35.0 | Solvent, carrier |

| GRANUGLASS expanded glass (0.1–0.3 mm) | 20.0 | Lightweight thermal insulation filler |

| Mineral fillers (silica, chalk) | 10.0 | Mechanical property enhancement, filler |

| Pigment (titanium dioxide) | 3.0 | Opacity, color |

| Preservative / biocide | 0.3 | Protection against microorganisms |

| Additives (anti-foam, flow improvers) | 1.7 | Stabilization and ease of application |

Description of Quality Control Methods and Laboratory Tests

1. Viscosity Control

-

Method: Measurement using Ford cup viscometer (Ford #4) or Brookfield viscometer.

-

Target value: 20–40 seconds (Ford #4) for optimal roller or brush application.

-

Purpose: Ensures proper paint consistency.

2. Density and pH Control

-

Density: Measured using a pycnometer or hydrometer.

-

Target range: 1.1–1.3 g/cm³.

-

pH: Measured pH should be between 7.5 and 9.0.

-

Purpose: Ensures chemical stability and application properties.

3. Solids Content

-

Method: Drying a paint sample at 105°C until constant weight.

-

Range: 40–50%.

-

Purpose: Controls concentration of solid components.

4. Thermal Conductivity and Solar Reflectance (TSR) Test

-

Method: Laboratory tests on cured coating samples (e.g., laser thermal conductivity measurement, spectrophotometer for TSR).

-

Values: λ ≈ 0.0005 W/(m·K), TSR approx. 90%.

-

Purpose: Confirms thermal insulation and solar reflectance properties.

5. Weather Resistance

-

Method: Aging tests in climate chambers (UV, moisture, freeze-thaw cycles).

-

Purpose: Checks color durability, adhesion, and coating integrity.

6. Resistance to Fungi and Bacteria

-

Method: Incubation of paint samples under conditions favorable for microbial growth and evaluation of growth.

-

Purpose: Confirms biocidal effectiveness.

7. Drying and Curing Time

-

Method: Measuring touch dry and full cure times under standard conditions (23°C, 50% RH).

-

Typical values: Touch dry 2–4 hours, full cure 24 hours.

-

Purpose: Ensures comfortable application and usability.

Application Instructions

Surface Preparation

-

Ensure the substrate is clean, dry, and free of dust, grease, loose particles, and old peeling coatings.

-

For highly absorbent or very smooth surfaces, apply a suitable primer or bonding agent to improve adhesion.

-

Moisture content of the substrate should be below 5%.

Application Conditions

-

Apply at ambient and substrate temperatures between +5°C and +30°C.

-

Avoid application in direct sunlight, strong wind, or imminent rain.

-

Relative humidity should be below 80% during application and drying.

Application Method

-

Mix the paint thoroughly before use to ensure uniform distribution of GRANUGLASS granules.

-

Apply by brush, roller, or airless spray.

-

Recommended dry film thickness per coat: 1–3 mm depending on insulation requirements.

-

For best results, apply two coats allowing 4–6 hours drying time between coats.

Drying and Curing

-

Touch dry after 2–4 hours (depending on conditions).

-

Full cure achieved after approximately 24 hours.

-

Protect the fresh coating from rain, frost, and mechanical damage during drying.

Storage and Transport Recommendations

Storage

-

Store in original, tightly sealed containers.

-

Keep in a cool, dry place protected from frost and direct sunlight.

-

Recommended storage temperature: +5°C to +30°C.

-

Shelf life: typically 12 months from the production date.

Transport

-

Transport in sealed packaging to avoid contamination and moisture ingress.

-

Avoid exposure to extreme temperatures (below 0°C or above 40°C).

-

Handle with care to prevent container damage.

Specific Testing Methods to Ensure the Durability of Thermal Insulation Coatings

Key testing methods that ensure the durability of thermal insulation coatings include assessments of physical properties as well as resistance to environmental and mechanical factors. The most important tests are:

1. Weathering Tests

-

Accelerated aging in QUV or xenon chambers – alternating exposure to UV radiation and water condensation simulates natural weather conditions, allowing evaluation of color stability, adhesion, and coating integrity in a shortened timeframe.

-

Thermal cycling tests – repeated heating and cooling cycles test the coating’s resistance to thermal stresses, preventing cracking or delamination.

2. Adhesion Tests

-

Pull-off adhesion test – measures the strength of the bond between the coating and substrate, which is critical for durability and resistance to peeling.

3. Mechanical Resistance Tests

-

Abrasion resistance tests – evaluate the coating’s resistance to mechanical wear, important especially for facades exposed to physical damage.

-

Impact and scratch resistance tests – assess the coating’s ability to withstand mechanical impacts and surface scratches.

4. Chemical and Moisture Resistance Tests

-

Water and moisture resistance tests – such as immersion or condensation tests, assess water absorption and the effect of moisture on insulation properties and coating durability.

-

Chemical resistance tests – evaluate the coating’s resistance to aggressive substances, important in industrial environments.

5. Thermal Conductivity and Insulation Tests

-

Thermal conductivity measurement – confirms the coating’s ability to reduce heat transfer, which is fundamental to its insulation function.

6. Microscopic Surface and Cross-Section Analysis

-

Detects microcracks, porosity, and defects that may affect durability and insulation effectiveness.

7. Biological Resistance Tests

-

Assesses resistance to fungal and bacterial growth, preventing coating degradation in humid conditions.

Summary:

To ensure the durability of thermal insulation coatings, a comprehensive testing approach is applied: accelerated UV and moisture aging, thermal cycling, adhesion, mechanical and chemical resistance, and thermal insulation performance measurements. This approach verifies that the coating will maintain its insulating and protective properties over long-term service in various operating conditions.