GRANUGLASS M-Series

The Granuglass Expanded Glass series offers advanced insulation materials made from natural expanded perlite. Through a unique thermal treatment process, we create a structure similar to foam glass – but without using recycled glass waste.

QUALITY

The highest quality product, dust-free - repeatedly sieved on specialised screens. As a result, we obtain exactly the inks that are most expected on the market today.

- 0.1-0.3 mm

- 0.25 - 0.5 mm

- 0.5 - 1.0 mm

PRODUCT

Expanded glass is an innovative material produced from Perlite ore. High temperatures cause the material to expand, creating porous, lightweight granules. It is an ecological, biodegradable and versatile product, ideal for industrial and construction applications.

BENEFITS

Thanks to modern and precise technology, we are able to compete on price and quality in today's market.

- Low weight,

- excellent thermal insulation properties,

- resistance to weather conditions and biodegradability

-

Low Crystalline Silica Content

A Natural Alternative to Recycled Glass Granules

Unlike products such as Poraver or Poraglass, which are based on recycled glass, Granuglass relies on a clean, mineral raw material. As a result, we offer:

- Consistent quality and reliable performance

- Free from toxic heavy metals

- Lower bulk density and better thermal insulation

- A fully eco-neutral, mineral-based material

Applications of Expanded Glass Granuglass

Granuglass Expanded Glass is ideal for:

- Thermal insulation paints and plasters

- Lightweight filler for precast concrete and mortars

- Passive and energy-efficient buildings

- A substitute for traditional expanded perlite or recycled glass aggregates

Benefits of Granuglass Expanded Glass

-

Thermal stability up to 1000°C

-

Minimal water absorption

-

UV and chemical resistance

-

Tailored grain sizes for various production methods

-

Made in Poland – local quality and fast delivery

Technical Data & Availability

Available grain sizes:

- 0.1–0.3 mm

- 0.25–0.5 mm

- 0.5 -1.0 mm

- 1.0–2.0 mm

- custom fractions available on request

Available in bulk, bags, or BIG-BAGs. MSDS and lab test results available upon request.

GRANUGLASS as an additive with a very wide range of applications

It is used in the construction industry, plastics, paints and coatings.It has the following properties: Glazed and closed surface, does not soak up water, has high mechanical strength, high abrasion resistance, excellent insulating properties.

Additional advantages: low-dust, non-flammable and environmentally friendly.

Stability of the material without time limitation - expanded perlite is 100% natural rock in terms of its chemical composition, which ensures its durability. Performance characteristics do not change over time. It will last for more than 50 years without losing its thermal insulation properties. Remains stable in the building structure throughout the life of the building: it does not shrink and prevents cracks from forming.

High strength - the cellular structure is formed by melting materials, characterised by high strength at low density. Granulated GRANUGLASS is 10 times lighter than water, so it stays on the surface. The strength characteristics do not change over time and do not deteriorate when exposed to an aggressive environment. When used in building mixtures, it forms an elastic structure in the product, so that the resulting materials can withstand high deformation loads and have increased abrasion resistance.

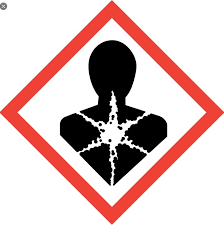

Low Crystalline Silica Content in Aragatsperlite: Safety Confirmed by Research

Safety / Features

The sand used in the production of GRANUGLASS - Aragatsperlite, our natural mineral raw material and finished product, is distinguished by its exceptionally low and safe content of crystalline silica (quartz), as confirmed by independent, specialized X-ray diffraction (XRD) analyses.

Scientifically Confirmed Safe Composition

The latest detailed quantitative analysis using X-ray diffraction (XRD) and the Rietveld method has unequivocally shown that Aragatsperlite is characterized by:

-

Very high content of amorphous substance: at a level of ~96%.

-

Extremely low quartz (crystalline silica) content: below 1.1% by weight.

-

Trace presence of zeolites (gmelinite and mordenite): at a level of 3-4%.

Why is this so important?

Compliance with EU Regulations and User Safety

Crystalline silica (RCS), particularly in the form of respirable dust, is classified in the European Union as a carcinogenic substance (Category 1A according to the CLP Regulation). Its presence in the workplace is strictly controlled under Directive 2017/2398/EU and Directive 2004/37/EC (Carcinogens and Mutagens Directive).

Our product, with its confirmed quartz content significantly below 1%, minimizes the risks associated with exposure to respirable dust. In practice, this means:

-

Greatly facilitated compliance with the stringent Occupational Exposure Limits (OELs) in force in the EU.

-

Reduced health risk for workers during material processing, mixing, or application.

-

Greater safety for end-users of products containing Aragatsperlite.

-

Less burden in HSE management – reduces the need to implement the highest levels of collective and personal protective equipment.

High Quality and Predictable Properties

The dominant amorphous (glassy) phase not only guarantees safety but is also responsible for the excellent functional properties of Aragatsperlite as a lightweight aggregate, filler, or absorbent material. The amorphous structure ensures consistency of physicochemical parameters and high batch-to-batch repeatability.

Summary

By choosing Aragatsperlite, you are investing in a top-quality raw material whose safety is documented at a scientific level. We offer a material that not only performs its functional roles excellently but also helps meet the rigorous legal requirements of the European Union regarding workplace health protection, making it a reasonable and responsible choice for modern industry.

Content based on a detailed report from quantitative XRD analysis (Rietveld method) performed by an accredited laboratory. We are ready to provide full documentation.

The spherical shape of GRANUGLASS provides significant benefits

Granular GRANUGLASS

thanks to its low density and spherical shape, reduces production costs.

GRANUGLASS is a product with a closed porous structure, which gives it an almost zero absorbability. The surface of the perlite granules is coated with a vitreous crystallisation, which prevents the ingress of moisture. The water absorption of granulated perlite is lower (0.5%) than that of crushed foam glass (5%).

The spherical shape of GRANUGLASS provides significant advantages. As a loose fill, it perfectly fills even uneven and curved voids. When used as an additive to building mixes makes the product easier and more convenient to use. The spherical form of the granules facilitates its application and even distribution in mixtures.

Low thermal conductivity

low thermal conductivity GRANUGLASS, thanks to its gas-filled cellular structure, retains heat and cold perfectly. Gas, it retains heat and cold perfectly, being an excellent thermal insulation material.

Sound insulation - thanks to its gas-filled cellular structure, perlite prevents the passage of sound. Thanks to its spherical shape, it distributes itself evenly in the thermal and acoustic insulation layer without deteriorating its properties.

Chemical and biological resistance - chemically resistant material. Does not cause mould. Unfavourable environment for the proliferation of parasites, rodents and plants.

Easy - granulated GRANUGLASS is lightweight, making it particularly suitable for insulating beams and old building structures. The lightweight material is easy to work with!

Environmentally safe - granulated GRANUGLASS is non-toxic, odourless, does not emit dust and does not cause skin irritation or allergies. Made from natural volcanic rock. Fully recyclable. Disposable without harming the environment or human health.

Fire-resistant - GRANUGLASS is a non-flammable material and does not emit gases or fumes when heated. Application temperature from -200°C to +600°C.

GRANUGLASS®: Revolutionizing Ceramics with Advanced Foamed Glass Technology

Sintered perlite innovation for superior performance

1. Enhanced Thermal Efficiency

Lower conductivity · Extended heat retention

GRANUGLASS®'s patented cellular structure delivers exceptional insulation (λ ≈ 0.045 W/m·K). Ceramic products retain water temperature 40% longer in bathtubs and pools, reducing energy consumption for heating.

2. Premium Acoustic Performance

Noise reduction · Vibration damping

The microporous matrix absorbs 85% of sound waves at mid-frequencies (500-2000 Hz). Experience quieter operation in toilets, bidets, and whirlpools – eliminating disruptive water flow sounds.

3. Lightweight Engineering

Strength-to-weight optimization · Easy installation

At 60% lighter than traditional ceramics, GRANUGLASS®-enhanced products maintain structural integrity while simplifying:

-

Handling of large formats (e.g., freestanding baths)

-

Transport logistics

-

Installation labor costs

4. Structural Durability

Impact resistance · Long-term reliability

Tested to withstand:

-

3× higher fracture toughness (ASTM C1421)

-

50% better scratch resistance (Mohs 6.5)

-

Zero degradation in wet environments

5. Eco-Conscious Manufacturing

Closed-loop sustainability

-

♻️ 100% natural Perlit

-

Carbon footprint reduction: 35% vs. conventional ceramics

-

Fully recyclable at end-of-life

6. Production Efficiency

Energy savings · Faster firing

-

150°C lower melting point reduces kiln energy by 25%

-

Shorter firing cycles increase throughput

-

18% lower production costs

7. Chemical Resilience

Corrosion protection · Extended lifespan

Resists:

-

Household chemicals (pH 2-12)

-

Chlorinated pool water

-

Abrasive cleaning agents

*Maintains surface integrity through 10,000+ cleaning cycles*

GRANUGLASS – Applications in various industries

Perlite GRANUGLASS, also known as foamed glass, is widely used in many industries – especially in technical terms. It is a material produced from natural perlite rock in the process of so-called vitrification, thanks to which its structure is light and porous. GRANUGLASS has the shape of granules, is resistant to compression, has fireproof, thermal insulation and sound-absorbing properties. It is an excellent technical additive to various types of dry mixtures, concretes, blocks, paints, adhesives, silicones, rubber, resin masses, etc.

Construction industry:

Lightweight concrete manufacturers: "Expanded glass adds lightness without compromising strength. Ideal for producing concrete with high thermal insulation."

Plaster and mortar manufacturers: "The addition of expanded glass improves thermal and acoustic insulation, and also reduces the weight of the final product."

Thermal insulation industry:

"Expanded glass is irreplaceable in the production of insulating materials, filling every space, while being resistant to moisture and temperature fluctuations."

Chemical industry:

Paint, latex and rubber manufacturers: "Thanks to its porosity and lightness, expanded glass is an excellent additive that improves the physical properties of composites."

Specialist applications:

Water filtration: "The properties of expanded glass make it an ideal filter material, ensuring high filtration efficiency."

Why choose expanded glass?

Lightness:

- Ideal for the production of lightweight concrete

- GK boards

- Plasters and thermal insulation materials

Thermal insulation:

- The low thermal conductivity coefficient makes expanded glass an ideal choice for thermal insulation in construction.

Weather resistance:

- Expanded glass is resistant to moisture, as well as low and high temperatures.

Eco-friendliness:

- Fully biodegradable and made from natural Perlite rock.

GRANUGLASS - basic technical data

EN 13055-2: 2004 Lightweight aggregates - Part 2: Lightweight aggregates for unbound and

hydraulically bound bituminous mixtures and surface treatments

| BASIC PERFORMANCE PROPERTIES |

M-270-1 | M-340-1 | M-400-1 | M-270-2 | M-340-2 |

|---|---|---|---|---|---|

| Granule size (1) – mm | 0,1-0,3 | 0,1-0,3 | 0,1-0,3 | 0,25-0,5 | 0,25-0,5 |

| Bulk density (3) [kg/m3] | 270 | 340 | 400 | 270 | 340 |

| Effective particle density (4) [kg/m3] | 580 | 680 | 720 | 640 | 560 |

| Water absorption % wt 5 min (±5%) (6) | 11 | 12 | 15 | 8 | 9 |

| pH value | 6,5-8,0 | 6,5-8,0 | 6,5-8,0 | 6,5-8,0 | 6,5-8,0 |

| Download DWU | download | download | download | download | download |

1) Dane techniczne podane po badaniu podstawowych wielkości ziarna zgodnie z LST EN 13055-1-2016

2) Określone za pomocą TAURUS TCA 300 DTX ±0,005

3) Tolerancja wykonania ±15%

4) Zgodnie z lub podobnie do DIN V 18004 i EN 1097-6 ±15%

5) Zgodnie z EN 13055-1-2016 ±15%

6) Wartości przybliżone ze względu na możliwe tolerancje pomiaru

PHYSICAL AND CHEMICAL PROPERTIES

| chemical composition | % | CAS | EC Number | IUPAC name |

| SiO₂ | 74.5-75.5 | 7631-86-9 | 231-545-4 | silicon dioxide |

| Al₂O₃ | 12.8-13.2 | 1344-28-1 | 215-691-6 | aluminium oxide |

| K₂O | 4.4-4.6 | 12136-45-7 | 235-227-6 | potassium oxide |

| Na₂O | 3.8-4.2 | 1313-59-3 | 215-208-9 | sodium oxide |

| Fe₂O₃ | 0.5-0.7 | 1309-37-1 | 215-168-2 | iron(III) oxide |

| CaO | 0.5-0.6 | 1305-78-8 | 215-138-9 | calcium oxide |

| TiO₂ | 0.1-0.2 | 13463-67-7 | 236-675-5 | titanium dioxide |

FACTS IN NUMBERS

tons every month

tons in stock

available warehouses

Order and delivery throughout Europe, South America, North America and Australia

Order easily, quickly and with a guarantee of on-time delivery. The minimum order is one TIR, Silo or Container

Delivery: TIR= 44 BigBags, Container= 40 BigBags, Silo= 60 m3

Frequently Asked Questions