GRANUGLASS

DOWNLOAD DOKUMENTS

Safety / Features

Low Crystalline Silica Content in Aragatsperlite: Safety Confirmed by Research

The sand used in the production of GRANUGLASS - Aragatsperlite, our natural mineral raw material and finished product, is distinguished by its exceptionally low and safe content of crystalline silica (quartz), as confirmed by independent, specialized X-ray diffraction (XRD) analyses.

Scientifically Confirmed Safe Composition

The latest detailed quantitative analysis using X-ray diffraction (XRD) and the Rietveld method has unequivocally shown that Aragatsperlite is characterized by:

-

Very high content of amorphous substance: at a level of ~96%.

-

Extremely low quartz (crystalline silica) content: below 1.1% by weight.

-

Trace presence of zeolites (gmelinite and mordenite): at a level of 3-4%.

Why is this so important?

Compliance with EU Regulations and User Safety

Crystalline silica (RCS), particularly in the form of respirable dust, is classified in the European Union as a carcinogenic substance (Category 1A according to the CLP Regulation). Its presence in the workplace is strictly controlled under Directive 2017/2398/EU and Directive 2004/37/EC (Carcinogens and Mutagens Directive).

Our product, with its confirmed quartz content significantly below 1%, minimizes the risks associated with exposure to respirable dust. In practice, this means:

-

Greatly facilitated compliance with the stringent Occupational Exposure Limits (OELs) in force in the EU.

-

Reduced health risk for workers during material processing, mixing, or application.

-

Greater safety for end-users of products containing Aragatsperlite.

-

Less burden in HSE management – reduces the need to implement the highest levels of collective and personal protective equipment.

High Quality and Predictable Properties

The dominant amorphous (glassy) phase not only guarantees safety but is also responsible for the excellent functional properties of Aragatsperlite as a lightweight aggregate, filler, or absorbent material. The amorphous structure ensures consistency of physicochemical parameters and high batch-to-batch repeatability.

Summary

By choosing Aragatsperlite, you are investing in a top-quality raw material whose safety is documented at a scientific level. We offer a material that not only performs its functional roles excellently but also helps meet the rigorous legal requirements of the European Union regarding workplace health protection, making it a reasonable and responsible choice for modern industry.

Content based on a detailed report from quantitative XRD analysis (Rietveld method) performed by an accredited laboratory. We are ready to provide full documentation.

Download DWU

GRANUGLASS product cards dedicated to each faction

M270-1

0.1-0.3 mm

270kg/m3

M340-1

0.1-0.3 mm

340kg/m3

M400-1

0.1-0.3 mm

400kg/m3

M270-2

0.25-0.5 mm

270kg/m3

M340-2

0.25-0.5 mm

340kg/m3

M270-3

0.5-1.0 mm

270kg/m3

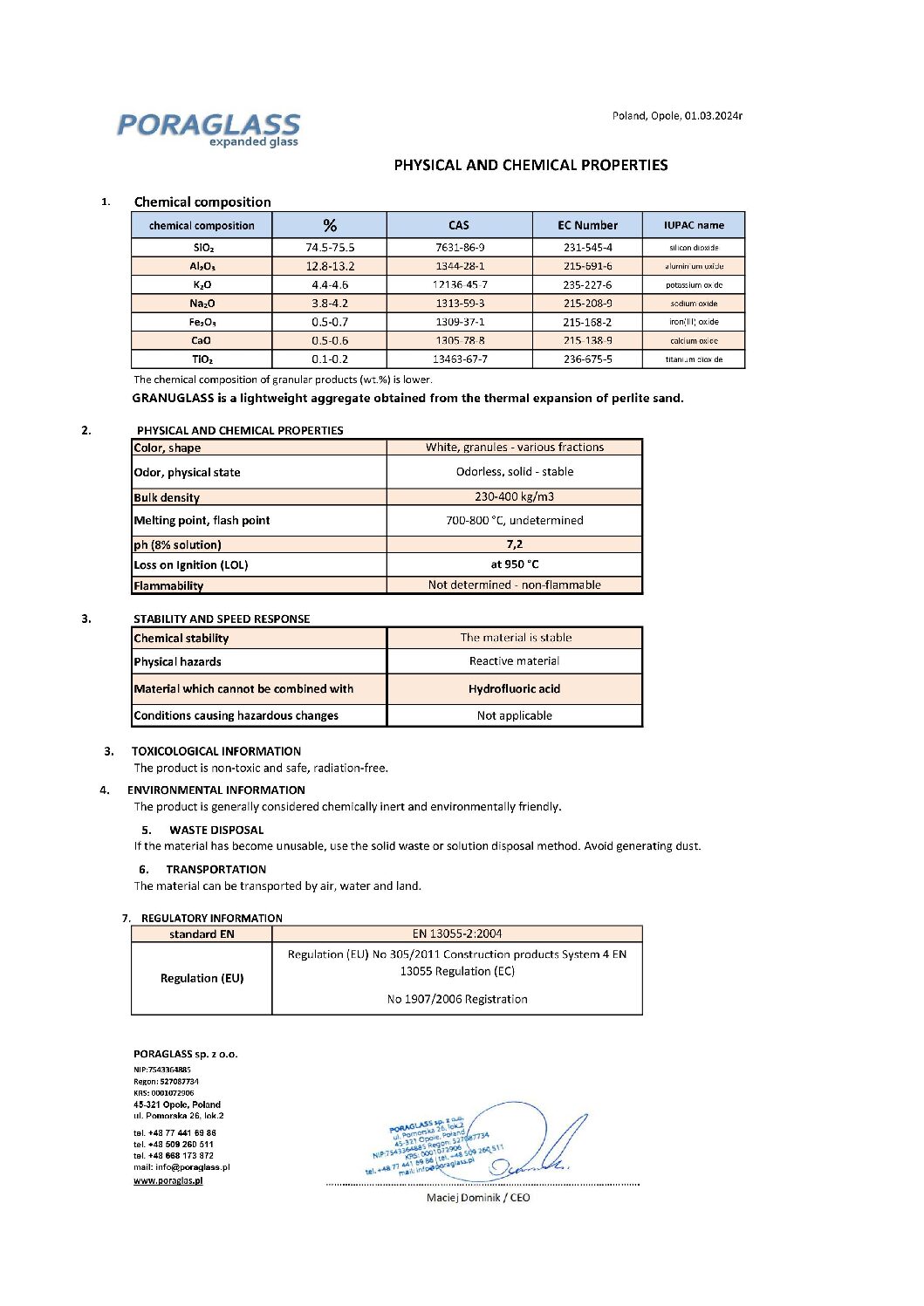

Physical and Chemical Properties

Material Safety Data Sheet PORAGLASS

PHYSICAL AND CHEMICAL PROPERTIES 2025